How Bass Diaphragms Are Made?

Bass diaphragms are the heart of low-frequency sound reproduction in speakers and earbuds. Their construction plays a vital role in delivering deep, punchy bass. This article breaks down the materials, manufacturing process, and considerations behind creating high-performance bass diaphragms.

Materials Used in Bass Diaphragms

- Paper (Pulp-Based): Treated or untreated cellulose materials are common due to their lightweight and natural damping properties.

- Polypropylene: Offers excellent moisture resistance and good balance of rigidity and flexibility.

- Carbon Fiber: Used in high-end drivers for its strength and low weight, delivering precise and punchy bass.

- Aluminum or Titanium: Hard, lightweight metals used for rigid diaphragms with fast transient response.

- Kevlar or Other Composites: Durable and stiff, used to resist distortion during heavy bass reproduction.

Manufacturing Process of Bass Diaphragms

-

1. Material Selection & Treatment

The first step is choosing the right diaphragm material based on intended sound signature and usage. Materials are often treated with damping compounds, coatings, or resins to enhance strength and reduce unwanted resonances.

-

2. Molding or Shaping

Materials like polypropylene or pulp are molded using heat and pressure to achieve the desired cone shape. Precision tooling ensures consistent thickness and curvature, critical for accurate bass response.

-

3. Bonding Voice Coil

The diaphragm is attached to a voice coil using strong adhesives. Alignment is crucial, as this coil will move within a magnetic field to drive the diaphragm back and forth, producing sound.

-

4. Surround Integration

A flexible surround (usually rubber or foam) is added to the diaphragm’s edge, allowing for controlled movement and preventing damage during large excursions.

-

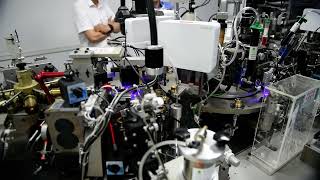

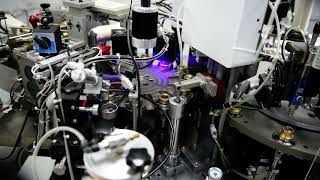

5. Assembly & Testing

The diaphragm, voice coil, and magnetic motor are assembled into the driver housing. Each unit is then tested for frequency response, distortion, and durability before final deployment.

Key Characteristics of Bass Diaphragms

- High Excursion Capability: Designed to move a large volume of air to reproduce lower frequencies effectively.

- Rigid Yet Lightweight: Ensures minimal flexing while allowing fast movement for accurate sound reproduction.

- Damping Control: Materials and coatings help suppress resonances that could cause distortion.

- Thermal Stability: Must withstand heat generated by the voice coil during extended playback.

Comparison of Common Bass Diaphragm Materials

| Material | Sound Profile | Strengths | Weaknesses | Common Use |

|---|---|---|---|---|

| Paper | Warm, natural bass | Lightweight, good damping | Moisture sensitive | Budget to mid-range speakers |

| Polypropylene | Balanced and smooth | Resistant to humidity | Less rigid than composites | Consumer-grade drivers |

| Carbon Fiber | Fast, tight bass | Strong and light | Expensive | High-end audio systems |

| Aluminum | Crisp and clean | Very rigid | May ring at certain frequencies | Premium woofers |

| Kevlar | Controlled and precise | Durable, good internal damping | Costly to manufacture | Professional studio monitors |

Conclusion

Crafting bass diaphragms is a balance of science and engineering. From material choice to manufacturing precision, every step impacts the final sound. Whether it’s deep rumble or tight punch, the diaphragm design determines how we feel the bass in music and media.

For high-performance bass diaphragms, partner with SPEAKER DRIVER™️, trusted by leading audio brands worldwide.