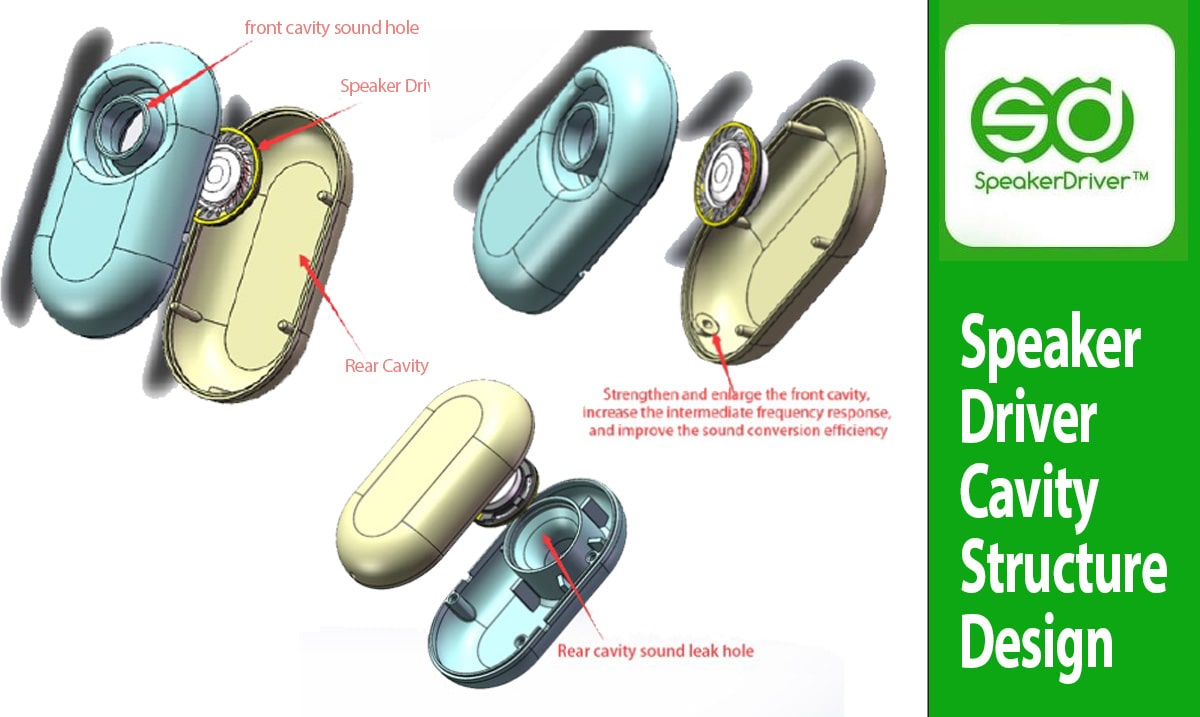

Speaker Driver Cavity Structural Design

The structural design of a speaker driver's cavity plays a critical role in shaping the overall acoustic performance. From rear vented chambers to front acoustic volumes, every component of the cavity architecture contributes to tonal balance, low-frequency response, and distortion control. As audio devices become smaller, precise cavity design has become essential for maintaining sound quality in constrained spaces like earbuds, wearables, and mobile electronics.

Key Elements of Speaker Cavity Design

- Rear Cavity (Back Volume): Acts as a compliance element and air spring; its size and shape directly affect bass extension and resonance behavior.

- Front Cavity (Front Volume): Influences high-frequency tuning and output efficiency; critical in open vs closed earbud designs.

- Acoustic Vents and Ports: Help regulate air flow and pressure, balancing SPL and minimizing distortion.

- Chamber Material and Shape: The rigidity and acoustic damping of cavity walls prevent unwanted reflections and standing waves.

- Seal Integrity: Proper sealing ensures predictable acoustic impedance, essential for consistent frequency response.

Cavity Types and Their Acoustic Effects

| Cavity Type | Description | Acoustic Effect |

|---|---|---|

| Closed Back | Fully sealed rear cavity | Controlled low-end, better isolation, limited bass extension |

| Rear Vented | Back cavity with pressure release ports | Enhanced bass, smoother diaphragm motion |

| Dual-Chamber | Two rear volumes connected via tuned passage | Wider frequency response, improved damping |

| Front-Ported | Acoustic port near diaphragm output | High-frequency tuning, SPL optimization |

Front and Rear Cavity Design Guidelines

Front Cavity Design:

- Function: Generates a high-frequency cutoff, enhances midrange clarity, suppresses unwanted high-frequency noise, and improves sound conversion efficiency.

- Height: Typically designed between 0.3–2.0 mm.

- Sound Hole Design: The height of the sound hole usually accounts for at least 25% of the driver’s diameter to maintain acoustic balance.

Rear Cavity Design:

- Function: Supports low-frequency response, reduces harmonic distortion, and improves overall sound clarity.

- Volume: The cavity height typically ranges between 3–7 cm³, based on the driver’s size and desired bass response.

- Leak Hole Design: Leak holes should be around 5 mm² each, and their number and placement should prevent obstruction during assembly.

Optimization Strategies for OEMs

- Simulate cavity response with FEM and BEM acoustic modeling tools before tooling.

- Minimize internal reflections by adding acoustic damping materials to cavity walls.

- Use tuned vents or Helmholtz structures to suppress resonant peaks.

- Ensure tight sealing between housing components to avoid acoustic leakage.

- Validate performance across temperature and humidity ranges during product qualification.

Applications in Modern Devices

In TWS earbuds, carefully designed cavities ensure rich bass despite the miniature form factor. In smartphones and wearables, cavity design enables directional tuning, improved loudness, and clearer vocals. For automotive tweeters or dashboard speakers, cavity design is used to reduce phase interference and spatial distortion.

Conclusion

Speaker cavity structural design is more than an enclosure—it's a precision acoustic instrument. For OEMs, investing in advanced cavity modeling and design iteration leads to superior sound quality, brand differentiation, and user satisfaction. As compact audio systems continue to evolve, cavity architecture will remain a key pillar of driver performance engineering.