Speaker Driver Quality Control: Ensuring Excellence in Audio Components

Quality control is paramount in the production of speaker drivers, as it directly impacts the performance and reliability of audio components. This article explores the rigorous quality control processes involved in speaker driver manufacturing, the state-of-the-art testing equipment used, and how industry standards and customer requirements shape the quality assurance practices.

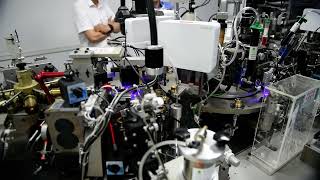

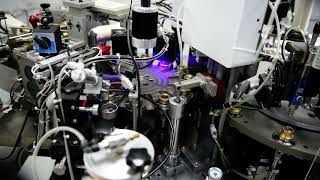

Advanced Audio Test Instruments

The quality control process begins with the use of advanced audio test instruments, which are crucial for ensuring that each speaker driver meets the required specifications. The R&D department utilizes 3 units of the SoundCheck system, a powerful electroacoustic and audio electronic measurement tool based on software. This system allows for customized test standards and methods tailored to specific technical indicators. The production department further ensures accuracy with 23 units of Zhaohua 6151 audio curve detectors and 18 sets of Sunshine audio frequency scanners. These instruments enable comprehensive testing of parameters such as frequency response, sensitivity, distortion, impedance, phase, and more, ensuring that every driver delivers optimal performance.

Quality Inspection Process: Ensuring Perfection

The quality inspection process for speaker drivers is thorough and multi-staged. After production, each driver undergoes a three-step testing process:

- Step 1: Sound Audio Testing: This initial test ensures that the speaker sound is normal, pure, and clear, free from any distortions or irregularities.

- Step 2: Frequency Curve Testing: A frequency sweep test visually checks key parameters such as sensitivity (accurate to 0.1 dB), distortion, impedance, FO (resonant frequency), and phase. This test is crucial for distinguishing between acceptable and subpar quality.

- Step 3: QC Sampling Inspection: To ensure the highest quality, a professional QE (Quality Engineer) conducts a sampling inspection on over 10% of the products. This final step helps guarantee that the speakers meet stringent quality stability requirements before packing and storage.

Quality Inspection Standards

The quality inspection standards for speaker drivers adhere to both national and industry guidelines, but the highest standards are set by the customers themselves. These customer-customized quality testing standards are combined with market differentiation to ensure that each product optimizes sound quality within the limited structural space of the speaker. Stringent quality testing standards, coupled with advanced testing instruments, are employed to guarantee the stability and performance of each driver.

Handling Defective Products

Even with rigorous quality control measures, defects can occasionally occur. There are three common types of defects:

- Poor Appearance: This is often caused by glue displacement during operation or foreign matter attachment during turnover. The solution involves using a special professional diluent to treat glue overflow and wiping away foreign matter with a clean white cloth.

- Poor Characteristics: These defects arise from insufficient fullness of glue during dispensing or instability of the diaphragm material. The remedy includes reapplying glue, but if the issue persists, the product must be scrapped.

- Poor Sound: This issue is generally due to a lack of magnetic saturation or an offset in the sound membrane combination. The treatment involves re-magnetizing the component, but if the coil and diaphragm combination is offset, the product is scrapped.

The company follows a stringent internal repair procedure for defective products, ensuring that only components meeting the highest standards are delivered to customers.

Conclusion

Quality control in speaker driver manufacturing is a meticulous process involving state-of-the-art testing instruments, rigorous inspection processes, and strict adherence to quality standards. By thoroughly testing each component and addressing defects with precision, manufacturers ensure that every speaker driver meets the highest standards of performance and reliability, providing consumers with exceptional audio experiences.

In this video, we take you through our rigorous quality check process for speaker drivers, ensuring that each product meets the highest standards of performance and reliability. From initial sound testing to detailed frequency curve analysis, every step is meticulously designed to guarantee pure, high-quality sound. Watch as we demonstrate the advanced testing equipment and procedures we use to detect and correct any defects, ensuring that only the best drivers make it to our customers. Discover how we uphold our commitment to excellence in every speaker driver we produce.