Super Linear Speaker Structure Description

Super linear speaker structures are engineered to deliver consistently high sound fidelity across a wide dynamic range without introducing nonlinear distortion. Designed with enhanced suspension geometry, voice coil alignment, and magnetic field symmetry, these structures ensure smooth diaphragm motion and minimal deviation even under high-excursion conditions. This is particularly valuable in compact audio devices such as TWS earbuds, mobile phones, and ultra-slim portable speakers.

Key Characteristics of Super Linear Speaker Structures

- Symmetric Magnetic Field: Dual magnetic gaps or extended pole pieces are used to stabilize flux density across diaphragm movement, improving linearity.

- Progressive Suspension: Custom-tuned spider and surround components allow for more controlled diaphragm excursion at high volumes.

- Centering Accuracy: Enhanced voice coil alignment reduces offset and asymmetry that can lead to THD (Total Harmonic Distortion).

- Low Mechanical Resistance: Super linear structures reduce resistance to diaphragm motion, allowing for more efficient sound reproduction.

- Extended Excursion Range: Designed for longer travel without loss of control, making them ideal for bass-heavy content in compact enclosures.

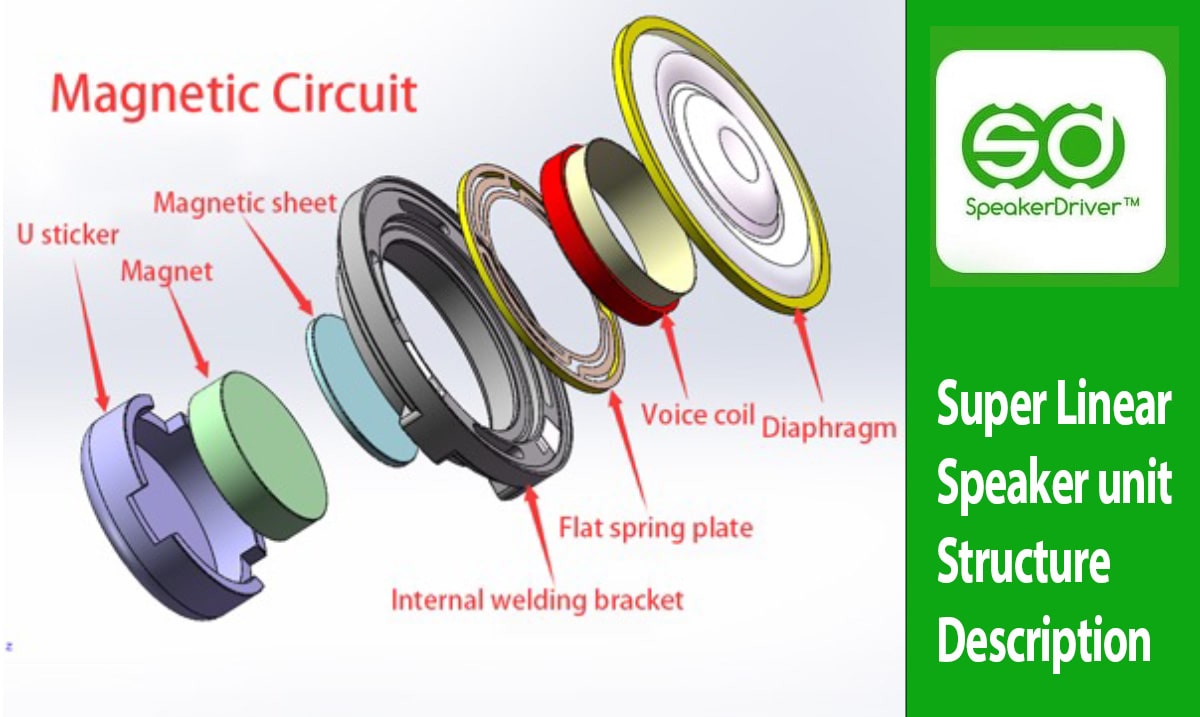

Main Components of Super Linear Speaker Drivers

- Magnetic Circuit System: Built with high magnetic flux density materials like neodymium iron boron magnets, and optimized gaps for a uniform magnetic field and high efficiency.

- Diaphragm: Constructed from lightweight and rigid materials such as paper, plastics, or metal to ensure fast response and wide frequency range.

- Voice Coil: Made from high-conductivity materials like copper or aluminum to reduce mass and enhance sensitivity.

- Support Structure: Includes suspension edges and folding rings that stabilize the diaphragm, reducing nonlinear motion during operation.

- Vent and Vent Groove: Integrated vent holes and grooves in the center magnet and yoke enable heat dissipation and cooling for prolonged operation.

- Planar Spring Plate: A linear-vibration spring plate that boosts power handling, amplitude, and frequency response while minimizing distortion.

- Assembly Process: Involves precise tooling and welding methods during material prep, magnetic circuit production, and final speaker assembly.

- Other Components: May include basket frames, magnetic covers, pole pieces, and high-frequency metal plates—all working together to ensure optimal functionality.

Comparison Table: Standard vs Super Linear Speaker Units

| Feature | Standard Speaker Structure | Super Linear Speaker Structure |

|---|---|---|

| Magnetic Field Symmetry | Single Gap, Varies With Excursion | Balanced Field With Dual Gaps or Extended Pole |

| Excursion Capability | Limited ±0.3mm | Extended ±0.5mm or More |

| Harmonic Distortion | Higher (THD > 1.5%) | Low (THD < 0.5%) |

| Suspension Type | Flat, Non-progressive | Progressive for Stability |

| Diaphragm Control | Standard Response | Improved Linearity |

| Heat Dissipation | Basic Air Gap | Integrated Vents and Grooves |

Applications in OEM Audio Products

Super linear speaker structures are favored in premium TWS earbuds, smartphones, and high-definition wearable audio devices. Their linear behavior allows for higher SPL output without distortion, critical for applications where space is limited but audio quality is a top priority. These drivers are especially suited to the compact dimensions required in modern mobile phones, offering high efficiency and reliability in long-term use.

OEM Design Tips for Super Linear Integration

- Use a symmetric magnetic circuit design to reduce flux imbalance.

- Select diaphragms with high rigidity and light weight (e.g., LCP or graphene).

- Implement progressive suspension systems to control excursion smoothly.

- Incorporate vent holes and grooves for effective heat dissipation.

- Consider planar spring plates to improve power and frequency response.

- Test for THD across the full frequency range to validate linearity benefits.

Conclusion

Super linear speaker structures represent a refined approach to micro-acoustic engineering. By minimizing mechanical and magnetic nonlinearity, and integrating advanced cooling mechanisms, these designs enable manufacturers to produce clearer, louder, and more faithful audio reproduction in devices with tight space and power constraints. For OEM developers seeking next-level performance in compact devices, adopting super linear architecture is a strategic and forward-looking decision.