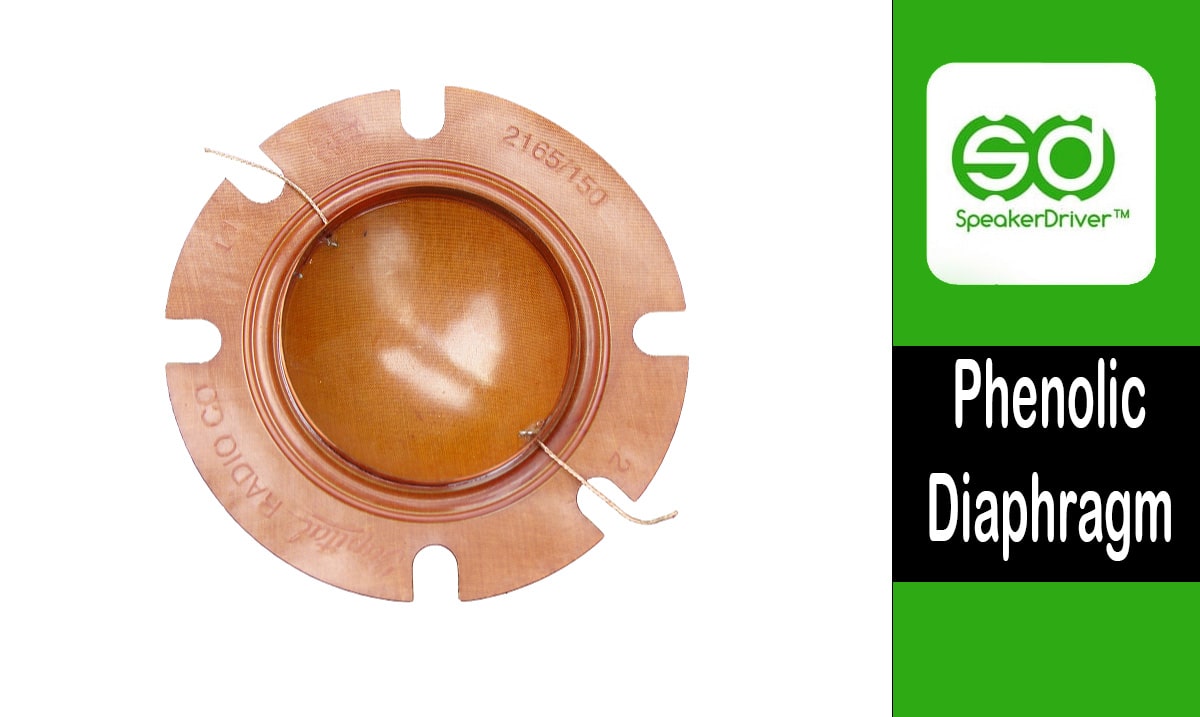

What is a Phenolic Diaphragm and Applications?

Phenolic diaphragms are a specific type of speaker diaphragm made from phenolic resin-coated cloth or paper. Known for their durability and moisture resistance, they are commonly found in horn drivers and public address systems. These diaphragms strike a balance between cost, strength, and performance, making them an ideal choice for certain audio applications.

Phenolic Diaphragm: Construction & Properties

-

Material Composition:

Phenolic diaphragms are made from a blend of cloth or paper fibers impregnated with phenolic resin, which is then molded under heat and pressure to form a rigid, stable diaphragm.

- Phenolic Resin: Provides rigidity, chemical resistance, and moisture protection.

- Substrate: Usually a cloth or paper base that adds flexibility and reduces weight.

-

Acoustic Properties:

While phenolic diaphragms may not deliver the same high-frequency precision as titanium or aluminum diaphragms, they offer a smooth and warm tonal characteristic, making them suitable for vocal reproduction.

- Frequency Response: Ideal for midrange applications; can handle frequencies typically between 500 Hz to 5 kHz effectively.

- Durability: Highly resistant to humidity, temperature variations, and mechanical stress.

-

Advantages:

- Cost-effective: More affordable compared to metal diaphragms.

- Resilient: Performs reliably in outdoor and high-moisture environments.

- Non-fatiguing Sound: Produces a warm, less piercing sound, reducing listener fatigue.

-

Limitations:

- Limited High Frequency: Not suitable for very high-frequency reproduction (above 10 kHz).

- Heavier Mass: Less efficient compared to lighter diaphragm materials.

Applications of Phenolic Diaphragms

-

Public Address Systems:

Phenolic diaphragms are commonly used in PA horns due to their ability to handle rugged use and environmental stress.

-

Outdoor Speaker Systems:

Their moisture resistance makes them suitable for outdoor installations in stadiums, theme parks, and industrial environments.

-

Midrange Drivers in Horn Loudspeakers:

Preferred in applications where clarity of speech is essential over extended periods.

-

Automotive Sound Systems:

Some automotive systems use phenolic diaphragms for mid-frequency reproduction where exposure to heat and moisture is a concern.

Comparison Table: Phenolic vs Other Diaphragm Materials

| Material | Sound Profile | Strengths | Weaknesses | Common Applications |

|---|---|---|---|---|

| Phenolic | Warm, smooth midrange | Durable, moisture-resistant, affordable | Limited high-frequency output | PA systems, outdoor speakers |

| Titanium | Bright, extended highs | High sensitivity and rigidity | Can sound harsh | Professional audio, high-end tweeters |

| Mylar | Balanced, budget-friendly | Flexible and lightweight | Lower power handling | Entry-level consumer audio |

| Aluminum | Clear and detailed | Good transient response | Can be brittle | Hi-fi tweeters |

Conclusion

Phenolic diaphragms offer a cost-effective and rugged solution for midrange sound reproduction, especially in environments where durability and moisture resistance are critical. While not designed for high-end audiophile precision, they serve reliably in public address and outdoor speaker systems, making them a dependable choice for voice-centric and rugged audio applications.

For reliable phenolic diaphragms and other speaker components, explore SPEAKER DRIVER™️, your trusted source in professional-grade audio solutions.